In 2016, EOS North America integrated its EOSPRINT software into Siemens’ NX software, kicking off a long partnership between the two that’s focused mainly on the advancement and adoption of industrial 3D printing. In 2018, Siemens provided automation and drive technology for EOS’s new M 300 Series and P 500 Series printers, and now the two have announced that their partnership is growing again. As part of this expanded agreement, EOS will integrate and resell Siemens’ AM software solutions with its own printers, which will unify the industrialized AM process in order to achieve more profitable AM factories.

In addition to making AM efficiency and profitability better, this integrated reseller agreement will give customers connectivity to upstream design and downstream production processes, and give them access to build preparation and optimization as well.

“With this agreement, EOS and Siemens can greatly improve the efficiency and profitability of the AM factory. Instead of only providing the build preparation for a single machine, customers can now leverage a unified process upstream to transform design, and downstream to realize high-volume AM factory production,” Aaron Frankel, Vice President of the AM Program for Siemens Digital Industries Software, said in a press release. “This unified process is critical for industrialized AM.”

This extended agreement makes it possible for EOS North America to resell products in Siemens’ industrialized AM solution as part of its Xcelerator portfolio, which has every phrase of AM development connected by one digital thread—the exact opposite of something called a point solution.

“Point solutions introduce time-consuming, error-prone inefficiencies into the AM workflow. Customers often have to interrupt their process to convert data for different software environments. And the problems with this approach are compounded with every change that’s required,” Frankel explained.

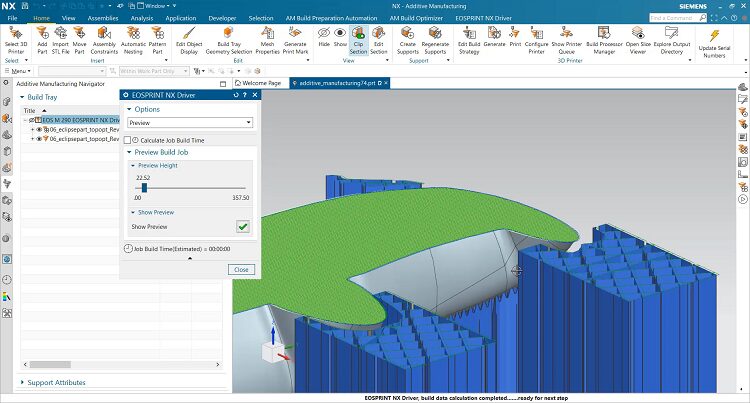

The integration of NX AM software with EOS’ job and process management software EOSPRINT 2 enables users to generate EOS build files directly in NX, defining material, exposure sets, and beam offset values, among other variables.

The integration of NX AM software with EOS’ job and process management software EOSPRINT 2 enables users to generate EOS build files directly in NX, defining material, exposure sets, and beam offset values, among other variables.EOS will integrate its own EOSPRINT 2 job and process management software solution with the Siemens NX software, as well as reselling the NX AM build preparation and AM Build Optimizer software to metal 3D printing customers so they can optimize their support structures and better orient their parts. By combining these two software solutions, EOS customers will be able to have access to and use all of Siemens’ AM capabilities, such as:

- build process simulation

- design validation

- materials engineering and durability analysis

- product lifecycle management

- scheduling and execution

- design for additive

- performance monitoring

- process automation

- topology optimization

With the ability to leverage all of these combined capabilities, EOS says that its customers can rest easy with the knowledge that their 3D printed parts have been created “to best accomplish their goals of first-time-right printing.”

“The ability to offer our customers a combination of Siemens’ AM software with EOS machines is an important step toward industrializing additive manufacturing for larger-scale production. We want to ensure that our customers can be as successful printing their first part today as they will their ten-thousandth part tomorrow, which means our machines must go beyond build preparation to connect to the entire end-to-end AM process,” Andrew Snow, senior vice president of EOS North America, said in a press release. “This new agreement with Siemens will help accomplish this and we’re excited to partner with Siemens as a reseller of their AM solutions.”

According to Andrew Snow, the senior vice president of EOS North America, the integration of Siemens software and EOS hardware, will help users “be as successful printing their first part today as they will their ten-thousandth part tomorrow.” After defining their build strategy in NX, users can also get previews of the layer-by-layer hatching pattern of their EOS-printed parts before they generate the files for EOSPRINT.

According to Andrew Snow, the senior vice president of EOS North America, the integration of Siemens software and EOS hardware, will help users “be as successful printing their first part today as they will their ten-thousandth part tomorrow.” After defining their build strategy in NX, users can also get previews of the layer-by-layer hatching pattern of their EOS-printed parts before they generate the files for EOSPRINT.One example is critical thermal components designer and manufacturer Sintavia LLC, which recently purchased two M4K-4 3D printers—basically stretched-out versions of the EOS M400-4. The company is taking advantage of the partnership between EOS and Siemens by building an end-to-end AM workflow that makes good use of the NX AM Build Preparation and AM Build Optimizer and NX AM Print Driver for EOSPRINT.

“This move by EOS North America to more tightly integrate Siemens AM software into its 3D printing systems perfectly aligns with our goal to create a seamless automated AM digital thread from design through production. If we’re going to make additive manufacturing a truly industrialized process, we need to ensure that the entire workflow is as efficient as possible,” stated Sintavia CEO Brian Neff. “A strong technical integration between EOS and Siemens software not only helps with build preparation, optimization and 3D printing, but it enables tighter connection to every other phase across the AM value chain.”

Siemens Digital Industries Software will train the EOS Additive Minds technical consulting team on how to use the NX AM and AM Build Optimizer software as part of the reseller agreement, and Additive Minds will teach EOS customers how to use Siemens’ AM software solutions. In addition, the companies have already agreed upon a framework that will offer comprehensive technical support.