Shapeways offers 3D printing on demand, enabling product creation at scale. But let’s take a step back: what exactly is 3D printing? What is additive manufacturing, and how is it used — and how is it different from 3D printing? Understanding the basics of additive manufacturing design, usage, and services will help you understand what Shapeways can offer as not just a service provider, but a solutions developer to help bring your ideas to the next level: production.

What are the types of additive manufacturing?

At its simplest, additive manufacturing is the opposite of subtractive manufacturing. That is, rather than subtract material such as is often seen in traditional means of production — think CNC milling, cutting, carving — additive manufacturing adds material to build a shape.

3D printing is a part of the additive manufacturing workflow, though the two terms are often casually used interchangeably. Seven ASTM-recognized 3D printing processes are the most common forms of this technology suite, and include:

- Material extrusion

- Material jetting

- Binder jetting

- Sheet lamination

- Vat photopolymerization

- Powder bed fusion

- Directed energy deposition

The history of additive manufacturing began with rapid prototyping applications — but the future is squarely in end-use manufacturing.

Design for Additive Manufacturing

Design for Manufacturing (DFM) is a well-established discipline; Design for Additive Manufacturing (DfAM) is a new set of skills specific to additive manufacturing.

Simply using an existing design file to 3D print a part will not likely result in a successful product. New ways of making have new design parameters, and existing designs can be optimized to better fit those new parameters to create a product tailored to the manufacturing technology used to create it. Additive manufacturing offers a freedom of design unprecedented in subtractive or molding processes. Geometries can be more complex, mass customization is possible, and internal structures can be created for complex one-piece designs.

DfAM leverages the unique capabilities of additive manufacturing including lightweighting, part reduction, and reduction of material and labor time and costs. When properly applied, DfAM allows for new ways of design — holes don’t have to be round anymore, and lattices can help provide the right amount of strength with less material, for instance.

Working with experts to design files offers immediate access to DfAM know-how.

Additive Manufacturing Materials

Plastic, metal, ceramics, and even food and living cells are among the materials that can be 3D printed. Most often, plastics and metals are used for the prototyping and production of new products.

Plastics

From early prototype to finished product, plastics are the most common material set in the additive manufacturing toolbox. These polymer materials may come in the form of filament, powder, resin, or pellet, depending on the 3D printing technology being used.

Some of the more common 3D printable plastics include PLA, ABS, TPU, and nylon. Reinforced and composite materials offer versatility and additional capabilities, such as strength or flexibility. Engineering-grade polymers like ULTEM and other high-temperature plastics also allow for high-performance end-use product creation such as might be seen in the aerospace industry.

The choice of plastic for a given project should take into account characteristics like finish, color, feel, and flexibility. Shapeways offers a large variety of polymer materials, like Nylon 12 (Versatile Plastic), which meets needs from prototyping to finished product, and Fine Detail Plastic, an acrylic material capable of extremely high detail. Flexible TPU, reinforced MJF Plastic PA12 Glass Beads, rigid polyurethane, and visually appealing Multi-Color Polyjet are just a few other options for extended capabilities.

Metals

An ever-widening selection of metals are also 3D printable, in the form of wire and, most commonly, powders. Metals like stainless steel, steel alloys, aluminum, and Inconel are becoming common in additive manufacturing. Metal-infused plastic filaments are also enabling metal production on desktop 3D printers. Metal materials require sintering after being 3D printed, and often smoothing processes to shine surfaces to the right finish.

Both directly 3D printing and lost-wax casting capabilities expand Shapeways’ portfolio to bring you the right choice in metal for your project. 3D printed stainless steel or aluminum offer the geometrical freedom to design in familiar metals, while lost-wax casting expands offerings to precious metals like platinum, gold, and more using 3D printed wax molds.

Ceramics

Whether for medical, high-temperature, or artistic applications, ceramic materials like porcelain are 3D printable. Ceramic materials are typically heat-resistant and/or biocompatible, lending their use to a variety of industries. Post-processing procedures like firing will generally be required to finish a ceramic 3D print.

Pastes

Paste materials can be extruded in often more experimental applications. Concrete 3D printing, for example, is becoming prominent in new construction approaches. Food such as chocolate or purees can also be extruded to create unique takes on food.

Bioprinting

While for the most part a future-looking area, bioprinting — that is, 3D printing using living cells — is a rising area of R&D. With an eventual goal of functional 3D printed organs for implant, to date most research has been on a much smaller scale, with successes seen with liver and kidney cells, as well as a small beating heart.

Additive manufacturing workflows

The full additive manufacturing workflow comprises design, print preparation, 3D printing, and post-processing. Design, leveraging DfAM know-how, creates the file from which the 3D printer will operate. Slicing prepares that file for the 3D printer, as each “slice” of the design will represent a layer of the additively laid-down material. The actual 3D printing is the stage in which a 3D printer produces the three-dimensional object, typically in a layer-by-layer process. Post-processing may involve very little work or a comprehensive several-stage finishing process to take the finished 3D print job to completed additive manufacturing project.

Post-processing/finishing

Often referred to as the “dirty little secret” of additive manufacturing, post-processing is a necessary step that follows the work of the 3D printer. Depending on the 3D printing process and material used, as well as desired end properties, any number of steps may be involved. Shapeways continues to expand on post-processing options for the right finish every time.

Among some of the most common post-processing steps are:

Unpacking

Powder bed 3D printing, as the name implies, uses a powder bed. Parts made in these processes must be unpacked from the full “cake” of powder, a process that generally involves manual excavation to “dig them out” as it were.

Powder removal

Once out of the powder cake, each part made on a powder bed fusion 3D printer must be cleaned of all excess powder.

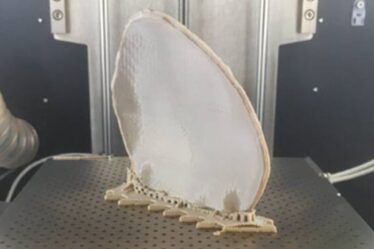

Support removal

Supports are required for FFF and SLA 3D printing processes, allowing for the three-dimensional building of each part. These supports are needed only during the 3D printing itself, and must be removed cleanly from each part after the build is complete, including sanding down or otherwise smoothing the points of connection.

Curing

Resin-based processes like SLA require parts to be cured to “set” the resin completely following 3D printing. Parts are only complete once they have been fully cured, often with UV light.

Firing

Just as traditional ceramics must be fired in a kiln, 3D printed ceramics must be fired to firmly set and solidify design geometries.

Sintering

Metal 3D prints must be sintered to firmly fuse all metal content, as a “green” part comes off most metal 3D printing processes. Sintering in a furnace removes all non-metal content, shrinking the part down by a known percentage from the 3D print to the final size.

Assembling

Any multiple-piece builds 3D printed part-by-part must be assembled manually. This most often applies to large builds that exceed the size of a single 3D printer build volume and instead have to be broken down into parts to be put together after printing.

Polishing

Metal 3D prints requiring a “shiny” appearance require polishing to remove the look of layering or other surface roughness.

Smoothing

Similar to polishing for metal prints, chemical smoothing processes remove the look of layer lines from polymer prints, creating a smooth surface finish.

Dyeing / Painting

Color is typically the final step in post-processing, through batch dyeing, painting, or other application of colorfast dye.

Applications of Additive Manufacturing

Rapid prototyping was the first application area for 3D printing. So tied together was this application to the technology that it was frequently called “RP”. As the technologies have developed, so too have applications. “3D printing” often referred to the work of makers and hobbyists using desktop 3D printers to create projects outside of prototyping, from game pieces to functional household items. “Additive manufacturing” is often used for industrial usage including end-use part production.

When to Use Additive Manufacturing vs. Conventional Manufacturing

The best application for additive manufacturing is complementary to conventional manufacturing. While in some cases additive manufacturing may displace conventional processes, additive and subtractive or molding technologies work best together.

Additive manufacturing can be applied effectively to low-volume manufacturing, mass customization, and highly complex, high-value parts. Conventional manufacturing processes are still best suited for mass production of alike parts, for instance.

Just as sometimes a hammer is needed and other times a wrench, it’s all about using the best tool — or process — for a particular job.

Ideal use of each type of additive manufacturing technology

Each 3D printing technology has its best-fit application areas. While some are well adapted for individual usage to create one-off parts, others can be scaled to manufacturing applications. Where and when are some of the most common applications for each technology?

Material extrusion

Perhaps the most common 3D printing technology, material extrusion — often referred to as FFF, or fused filament fabrication — uses an extruder to lay successive layers of material, most often in the form of plastic filament. Many desktop 3D printers use this technology; it is the most widely available for personal use. FFF 3D printing is well-suited for all stages of prototyping, from rough idea to functional prototype; for making tooling, jigs and fixtures; and for use among makers, hobbyists, and designers. Engineering-grade polymers, metal- or ceramic-filled composites, and other advanced materials also make extrusion-style 3D printers appropriate for some end-use production applications.

Material jetting

Most material jetting processes use liquid photopolymer droplets, which are then cured layer-by-layer with UV light. This process is best understood as being somewhat similar to inkjet (2D) printing. Material jetting is an industrial additive manufacturing process typically requiring a large 3D printer, and can be used for prototyping and end-use parts. Some material jetting systems enable color 3D printing.

Binder jetting

Binder jetting uses a liquid binding material to bond powder materials. The process can be thought of as an intersection between SLS and material jetting technologies. Binder jetting can be done with metal or sand materials to create, respectively, prototype or finished parts, or sand molds.

Sheet lamination

Sheets of metal or even paper material can be bonded together using sheet lamination 3D printing processes. For metal materials, ultrasonic additive manufacturing uses ultrasonic waves and mechanical pressure to bond layers. Laminated object manufacturing uses an adhesive coating to bond sheets of paper or plastic. Especially when using paper, material costs are quite low for sheet lamination. Geometries are not often highly complex given the methodology in these processes, gearing them more toward prototyping usage.

Vat photopolymerization

Stereolithography (SLA) and digital light processing (DLP) processes are classified as vat photopolymerization processes, in which liquid photopolymer in a vat is selectively cured by light-activated polymerization. These processes can be quite complex, down to the micro scale (microstereolithography) and can create some of the most detailed 3D prints. Applications range from prototyping to mass production. Nearly every hearing aid and orthodontic aligner on the market today is produced using SLA technology, as are many jewelry molds.

Powder bed fusion

One of the most common industrial additive manufacturing processes, powder bed fusion (PBF) uses thermal energy to selectively fuse regions of a powder bed. PBF processes include selective laser sintering (SLS) — using a laser — and electron beam melting (EBM) — using an electron beam. Plastics, metals, and ceramics can be 3D printed using PBF processes, creating prototype and end-use parts.

Directed energy deposition

Directed energy deposition (DED) melts materials, generally metals, as they are deposited. This process has the capability to repair and maintain existing structures, as a laser mounted on a multi-axis arm can move around relatively freely to lay down focused material. Maintenance and repair (MRO) applications are the most common for this process, which often requires post-processing to smooth the generally large layers.

Additive Manufacturing Pricing

Once the decision has been made to use additive manufacturing by engaging a service bureau, one large question remains: pricing.

Shapeways lays out clearly its pricing structuring, from engaging a designer to simply uploading a model for an instant quote.

Among the considerations for our pricing are:

- Materials:

- Material Volume

- Machine Space

- Number of parts

- Production

- Bounding Box Volume

- Support Volume

- Manufacturing Speed:

- Shipping cost

- Taxes

Bulk pricing is also available for large orders. See our pricing overview here for full details.

Customer Examples

As popular wisdom holds that “show, don’t tell” is the best way to prove a point, we’d like to share some examples of customer work achieved through the Shapeways platform. Just a few of our customer successes include:

Quantum Systems

Taking to the sky, drones are already high-tech — but 3D printing brings them to new heights. Quantum Systems specializes in making advanced eVTOL (electric vertical take off and landing) drones. These are anything but hobbyist toys, as the Quantum Systems team recently tested their Trinity F90+ to deliver medical samples. These machines must be robust, complex, and lightweight, lending their manufacture ideally to incorporating 3D printing.

Quantum Systems’ CEO, Florian Seibel, explains, “The complex geometry of 3D-printed parts saves weight by using synergy effects. With synergy effects we mean that with 3D-printed parts we are able to reduce the total number of parts by designing multiple-use parts with integral functionality.”

My Track Technology

“All-terrain vehicle” may not be the first application to spring to mind for 3D printing, but My Track Technology (MTT) used the technology to slash time and costs in their production process. Rapid prototyping and strong end-use 3D printed parts brought their eco-friendly, electric remote-controlled track vehicle to life for use in extreme terrains.

Michael Martel from MTT sums up the experience of working with Shapeways to develop the machine in three key benefits: “Speed, cost and simplicity. When our 3D drawing is finished we don’t have to produce fabrication drawings. We just upload the 3D file on Shapeways’ website. Very simple. We also do not have to build a mold for 1 up to 50 parts. It’s very great cost saving. Later when the design is perfect we can build a mold and be confident that the mold will meet our requirements. We are also not limited to a particular shape with 3D printing, practically every shape is possible. Finally, the precision, repeatability and tolerances are better than most of the others manufacturing methods.”

Cityscape Rings

Unique jewelry design is an excellent showpiece for 3D printing. The Cityscape rings emerged from designer and trained goldsmith Ola Shekhtman, who loves architecture and travel, and sought to capture iconic landmarks in a wearable way. She debuted her Cityscape collection in 2015, and has sold well over 6,000 rings through her e-commerce shops.

She says of 3D printing, “3D gives me three kinds of freedom: 1. Geographic freedom. I can live where I want and travel all year long, and the only tool I need to have with me is my laptop. 2. Freedom of creativity. Details rule! Customers adore buildings with columns and tiny statues, which I create in 3D software. It is tricky to pierce windows [by hand] and 3D lets me make it easily. And, 3. Freedom of time – To make 1000 rings by hand I would spend nearly 100 years. Shapeways can produce this amount in 2-3 weeks. Using 3D modeling I can make a city once and it is available to order in any quantity, forever, which frees me up for new designs.”

LuxMea

A standout design case for 2020 emerged from LuxMea Studio, which specializes in computational design and fabrication. The company developed its customizable Nuo Masks, intended for comfortable, durable, reusable fit for each individual’s face. Rapid prototyping and reliable bespoke mask manufacturing showcases 3D printing for mass customization — and for pandemic safety with style.

The LuxMea team explains: “We have been working with Shapeways since early 2016 and Shapeways has always been our trusted and go-to partner for commercial 3D printing production. We had a meeting last year and discussed the possibility for mass customization. The Shapeways API allows certain software platforms to export files directly to Shapeways, without the need of manually uploading each file. Without Shapeways’s API, we would have to limit the quantity and increase the cost to account for manually uploading and checking for each file.”

Please contact us today to learn more about our offerings and how we can help you every step of the way for your next project.