Italian industrial 3D printer manufacturer Wasp has just released the latest addition to its range of industrial and architectural 3D printers, the Delta Wasp 3MT Concrete.

As you can guess from the product name, it is a concrete mortar printing device in a delta-type printer configuration. The new variant architectural printer has a build volume of 1000 mm diameter x 1000 mm height.

The smaller size is aimed at customers wishing to produce modular concrete products rather than full size abodes. So smaller prefab structures, furniture, even piping and other smaller items can be printed depending on which nozzle is selected.

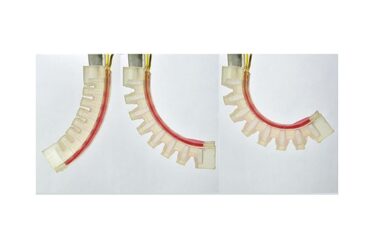

As standard, the printer comes complete with the LDM WASP Extruder XXL screw extruder, which has a nozzle diameter range of 8mm to 30mm. This is better suited to larger, faster prints.

The XXL version can print concrete mortars with a maximum particle size of 1 mm, fiber reinforced concrete, foamed concrete, clay, porcelain and earth-based mixtures with natural fibres.

A smaller extruder, the LDM WASP Extruder XL is better suited to precise, higher quality prints and has a nozzle diameter of 4mm to 8mm.

So how much will this all cost?

According to the WASP website, the Delta Wasp 3MT Concrete 3D printer with the XXL extruder will set you back 54,850 Euros for the basic package.

That package includes the XL extruder, the 80 liter mortar pump, the plastic conical nozzles, 5 metres of tubing, the delta assembly, the metal safety enclosure and the MDF/pallet printbed which allows for easy removal with a forklift.

Using the system appears to be fairly user friendly. The CAD slicing is performed in the same way you would with any FDM print job. A licence for Simplify3D is included.

The slicing and G-code are done in the separate software, and like any other printer the files are sent to the printer controller hardware either by WiFi or USB. Once the G-code is selected on the printer hardware, pumping parameters can be changed via the pump controller to ensure optimum printing, based on the material being used.

Once running, users can sit back and let the job run its course and monitor remotely via the printers onboard, connected cameras, and if there should be some issue, Wasp offer remote diagnostics and assistance from their team of connected technicians.

If you’d like to see more of the Wasp range of printers, which focus on a variety of ceramic and polymer delta type machines for industry, you can learn more about them over at this link.