Belgian-based AI manufacturing software company Oqton raised $40 million today through a round lead by Fortino Capital, PMV, and Sandvik. According to the firm, “several angel investors, including Carl Bass (former CEO Autodesk), Dries Buytaert (Drupal and Acquia), and Peter Mercelis (Layerwise) also participated in the round.” The company will use the money to improve its software especially for verticals such as 3D printing.

“We are keen to have new investors on board who can help us scale globally, with both a direct and indirect sales approach,” CEO, Ben Schrauwen, said. “We truly think the time has come for the manufacturing space to embrace the cloud and we are working hard to facilitate this.”

Oqton has an infuriating name, which I’ll always tend to misspell, but a real A-list group of engineering firms and people connected to it. The company is also defined by a rather big idea. In engineering and manufacturing companies now, a jumble of software mismanages the meandering paths a file may take to turn into a product. We have PLM software that should unify all, MES for manufacturing, CAD for authoring, QMS for quality, and then files are stored somewhere, too.

It’s a bit of a tangled web really and many firms struggle to do this efficiently and cost-effectively. Many different programs also represent risks for users and security. Oqton now wants to replace all of this “engineering middleware” with one solution that can track, optimize, and manage the entire process, including final manufacturing methods. It’s kind of a SAP dream acquisition, or an attempt to do over from scratch the CAD toolchain for the 3D printing age.

What makes Oqton notable is not that it has a grand vision that it hopes to power through an ever-widening circle of ever more gullible VCs. Instead, it is that the company claims to realize actual business benefits and savings on operations right now. That’s what makes it go from cute idea to something that you may want to explore now. With a lot of companies entering additive and setting up processes to be tied to, it is a very opportune time to tell people to switch out the digital tools as well as the physical ones. If the company can make good on its optimization promises, then it may have a very promising future.

But, what exactly does this company do? The name makes it sound like they are a bottom of the bin pharma company name-bought commercially (Ask your doctor about Oqton for instant pain relief for your hemorrhoids). Or it’s the name of a killer robot company made for when the Boston Dynamics robots strike back after years of abuse (Your Tactical Home Security Solution: Oqton).

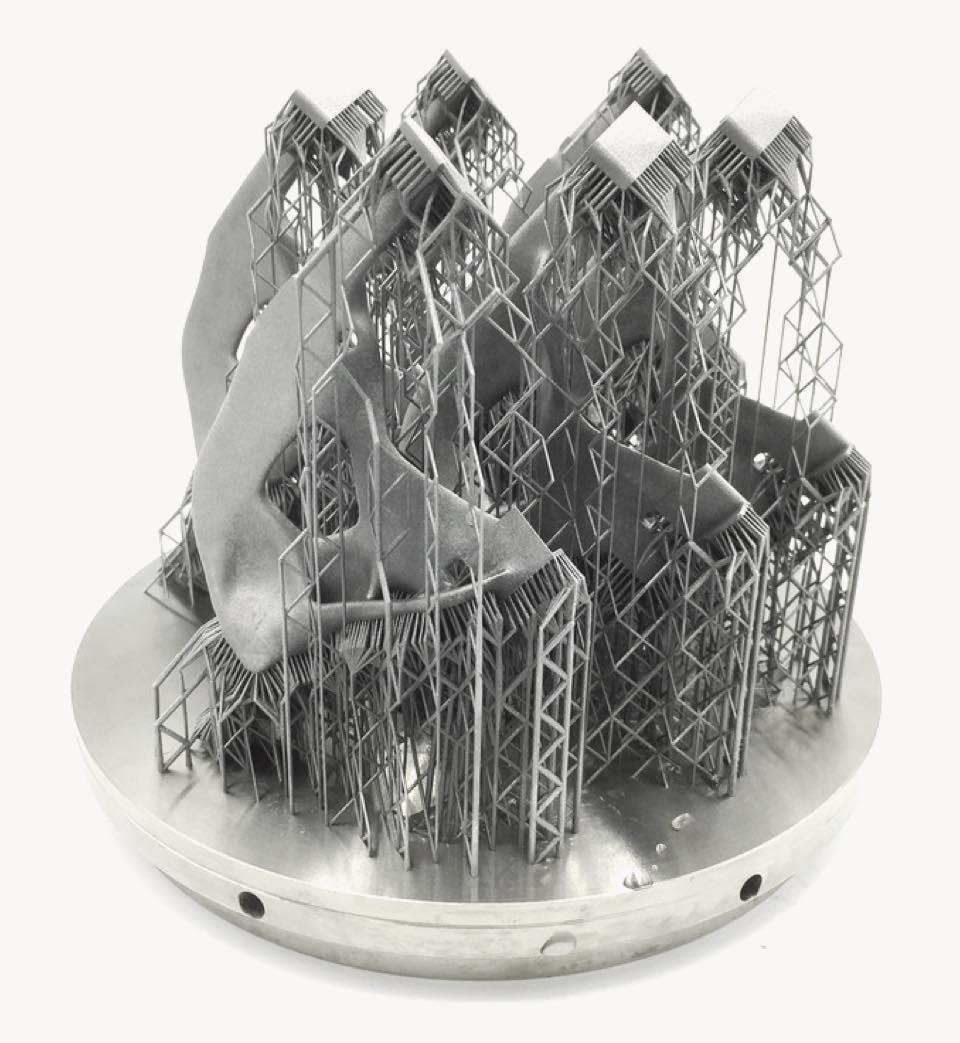

With Oqton you can automatically generate topology optimized parts according to set rules. AI-driven optimization of these topologies can marry them to best fit the proposed solution. You can create dynamic lattices, classify parts, and automatically generate tool paths. Dynamic nesting can optimize the build that you want to make to be the best in terms of time or cost, as well. The tool also simulates, schedules builds, and monitors them. You can analyze production processes, trace parts, and track inspection reports. Almost everything that you would need to make an optimized 3D printed part is done by one single tool.

“We can already achieve 100% automation in the dental and jewelry verticals, resulting in 30% overall cost reduction,” said Oqton Co-Founder Samir Hanna. “Given the platform strategy, the software can be targeted to many specific industry verticals, like dental, jewelry, medical, industrial and aerospace, as well as to different personas and workflows within those industries.”

I’m very excited by Oqton’s promise. The idea of having one toolchain part, powered by AI to boot, that can automate a large number of tasks typically performed manually would make it a very welcome product for many people. At the moment a significant number of dental, jewelry and hearing aid file checking and positioning is still done by hand while we make millions of parts this way. If we want to move more into production optimization tools such as Oqton will be needed. At the same time, to optimize and align processes using AI, based on much of the data needed for production, could prove to be very valuable indeed. If it meets its promises, Oqton will be a valuable tool indeed.