From the ability to offer greater speed and efficiency in manufacturing without added headaches like tooling and setup costs, to seeing products off to market faster, the list of advantages in using 3D printing continues to grow along with all the continued new offerings in hardware, software, and materials. Nothing can hold a flame to the most pivotal benefit in digital manufacturing though, with the ability to customize and manufacture sophisticated parts and products like never before.

As both a pioneer in additive manufacturing and a transformative leader in mass customization, Shapeways collaborates with an incredibly diverse range of customers who are heavily involved in the design process, as well as choosing materials, technology, colors, textures, finishes, and options for shipping and packaging.

Mass Production vs. Mass Customization

In stark distinction from mass production, the ability to mass customize entails meeting the detailed needs of Shapeways customers as product development intersects with manufacturing of the future. Whether a business may need low-batch production or manufacturing on the mass scale, Shapeways delivers with choices for over ten different technologies and 90 different materials.

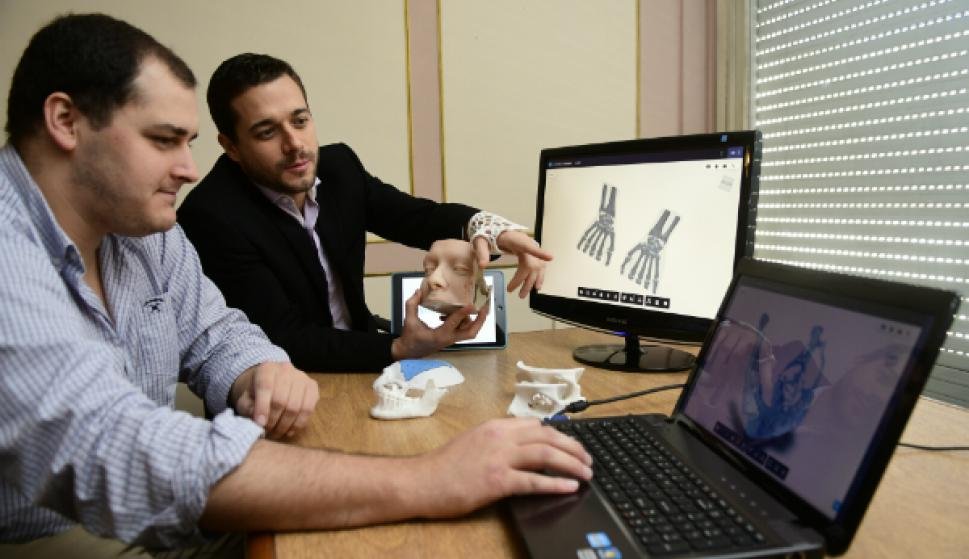

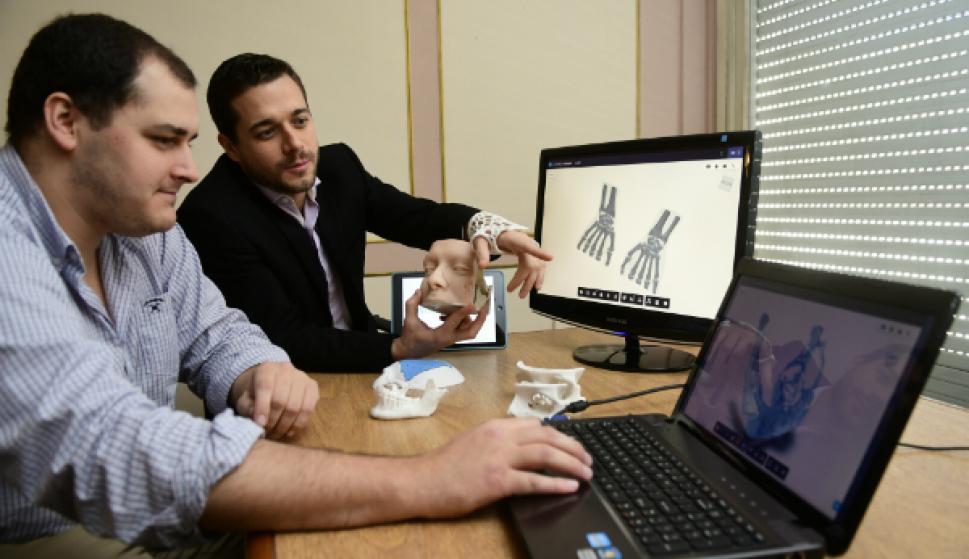

For example, industrial customers engaged in production of hundreds or thousands of parts may rely on Shapeways 3D printing services for Selective Laser Sintering (SLS) with durable materials like Nylon 12 [Versatile Plastic] or Nylon 11 [PA11 (SLS)], while for other applications they may look toward Mimaki 3D printers with High Definition Full Color for vibrant models made to suit for applications like medicine or architecture, as well as incredibly popular tabletop gaming miniatures.

The previous ‘way of doing things’ meant that mass production was completely controlled by the manufacturer, offering products with a set limit in terms of choices—and often none at all. From CNC machining to injection molding, traditional manufacturing ruled for decades, with highly customized or tailored products relegated to expensive, handmade items from the artisan realm. Consumers were confined to making choices based on what each business decided to sell in bulk and present to them. If the masses were not interested in particular items, then they had to be discontinued so the bottom line was not substantially affected with identical products rolling off assembly lines in bustling factories.

These days however, competition is fierce in the marketplace, and there has been a notable shift. Consumers are making their demands known for personalized products, realizing that one size does not have to fit all. For many, mass consumption has lost its appeal and minimalism has become the trend—whether in their home wardrobes or at warehouses where companies are tired of paying to keep large stocks of inventory that may just be collecting dust.

3D printing offers the perfect balance for saving on resources, adding new levels in sustainability for manufacturing, while serving a multitude of extremely useful applications that many of us are just learning more about, from futuristic drone technology to bespoke face masks. As consumers are busy making their exact preferences known, businesses are learning more about their target audiences and exactly where they are willing to invest their money.

Increased Customer Satisfaction with 3D Printing

With the ability to innovate at will and upload as many as 20 3D models at any time to Shapeways for 3D printing, the possibilities are truly infinite. Along with that comes the opportunity to collaborate in mass customization whether in producing devices for popular consumer goods or medical models that offer surgeons the ability to vastly improve or even save lives. In taking advantage of on-demand 3D printing, businesses can enjoy a streamlined system for customized products and orders that are sent directly to Shapeways for expedient 3D printing as needed.

Not only that, with on-demand production, 3D printed orders can be shipped out directly from Shapeways in customized packaging kept on site for fulfillment.

Every project is different at Shapeways, and every 3D print is unique. As many or as few customizations can be chosen on any scale, leading to low-volume or even mass production runs, quickly and efficiently. The LuminoGO is a great example. The Austrian-headquartered company Lumino was motivated to update the typical mask design, making it less disposable, as well as more comfortable and sustainable as a product overall. Available in 17 different configurations, Shapeways 3D prints the LuminoGO in multiple colors, with Lumino reporting amazing quality. The custom mask is ventilating and sterilizing and also includes a microphone, speakers, and even Bluetooth for ease in taking calls.

Producing the ultimate in bespoke masks, LuxMea Studio, headquartered in Toronto, also turned to Shapeways for 3D printing when mass customization of their product—the NuoMask—was required. Fitted to the consumer via artificial intelligence (AI), these incredibly progressive masks not only protect the health of the wearer, but offer sophisticated style in design, and better fit for individuals wearing glasses.

Explore other examples of mass customization case studies from Shapeways here.

About Shapeways

Contact Shapeways now to enjoy the benefits of advanced technology and materials for 3D printing creations for the classroom with accuracy, complex detail, and no limits in terms of mass customization or single part orders. Shapeways has worked with over 1 million customers in 160 countries to make over 21 million parts!Read about case studies, find out more about Shapeways solutions, and get instant quotes here.