3D printing in construction continues to expand in Japan, driven by the need for more efficient, affordable processes, and higher-performance materials overall. In developing new technology for the construction industry, a research group from Gifu University (Gifu, Japan) has been joined by:

- Construction Technology Research Institute

- Sumitomo Osaka Cement

- Shimizu Construction

- NIPPO

- Maruei Concrete Industry

- FTS

Along with innovation in dry and wet spraying, the research and development group has now built a printer for on-site work, which the group states offers multiple benefits in combination with information communication technology (ICT) equipment. Typical modes of construction worldwide involve molding poured cement into shape using formwork. In Japan, the Ministry of Land, Infrastructure, Transport, and Tourism recommends pre-casting with factory-made products; however, the researchers continue to move forward in refining technology—allowing a shift and employing a novel technique.

Undoubtedly, the research and development group is headed in the right direction with a focus on 3D printing. For industrial users—and especially in construction—the benefits are considerable. Greater affordability is possible on numerous levels, due to less time spent in production, transportation, less waste in materials, and reduced need for human laborers as well (becoming even more relevant with the greater use of more complex robotics).

With dry spraying, materials must be ‘separately conveyed’ and then sprayed from the nozzle tip, while wet spraying involves premixed materials being sprayed from the nozzle tip. With the team’s unique hybrid system, they are able to bring together all the benefits of both.

Outline of hybrid spraying system Source: Gifu University, Research Institute of Construction Technology, Sumitomo Osaka Cement, Shimizu Construction, NIPPO, Maruei Concrete Industry, FTS

The new process works in the following steps:

Powered by Aniwaa

- 3D modeling is performed on-site with spray nozzle attached to bucket tip of the ICT construction machine.

- Infinite plane design data is created, controlling the horizontal axis.

- Height is adjusted with an offset function.

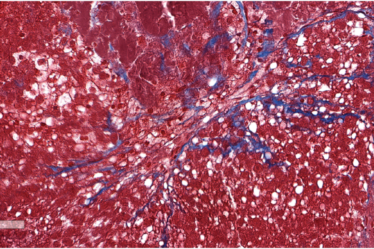

Experiments at the Construction Technology Research Institute. Formwork from the left, wall Source: Gifu University, Research Institute of Construction Technology, Sumitomo Osaka Cement, Shimizu Construction, NIPPO, Maruei Concrete Industry, FTS

“By using such ICT construction machinery technology, in the experiment of the Construction Technology Research Institute, we succeeded in directly outputting 3D concrete structures assuming a formwork (pillar) with a height of 1.5 meters and a wall with a height of 1 meter,” explained the researchers.

There are plans to deal with difficulties in transportation of materials, which is often an issue in the construction industry—for numerous applications. The team currently envisions “a buried formwork for construction of concrete structures” in their first phase, with newly applied accuracy and management in the second phase—to be used in abutments, piers, and more. In the third phase, they will be working on infrastructure like bridges, and other structures like railings.

Expected future application of bridge superstructure Source: Gifu University, Construction Technology Research Institute, Sumitomo Osaka Cement, Shimizu Construction, NIPPO, Maruei Concrete Industry, FTS

As the research and development group moves from the conceptual phase to actually completing all three phases, it will be interesting to see the end results. While there are true benefits for use in the building industry, many have expressed skepticism as projects are slow to get off the ground, whether in building homes or entire villages.