When we hear the phrase “3D printed bearing” the first thing that may come to mind are the many videos of YouTubers testing if you can print balls in-situ inside a bearing case. The answer is yes, you can. They tend to be a bit inefficient, and grind quite a lot.

Some polymers however, have such low friction that they can serve as the bearing itself, minus the moving parts. Plastic specialists Igus have a range of these bearings available on their site, offering customers the opportunity to swap out their old linear bearings for a smooth plastic replacement.

Additionally, the company has made their polymer available as a filament, so users can print low friction bearings at home (with models from their GrabCAD page), or they can use the Igus in-house 3D printing service which offers printing for obsolete or custom parts based on their inventory.

Igus Filament

Igus makes a lot of plastic equipment for motion systems, such as polymer bearings and plastic nuts. These products are designed to be resistant to the operating environment (chemical/heat etc) and generally they have low friction coefficients when paired with various shafts and rods.

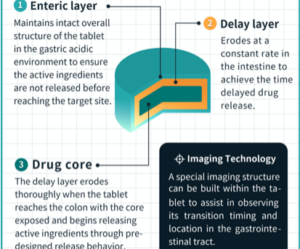

Specifically their low friction polymers (such as iGlide) feature a mix of base polymers, fillers and fibres, and solid lubricants, the latter making the bearings completely self lubricating.

You can see more about the iGlide polymer from which the filaments (and powders) are made in the video below.

GrabCAD

So you’ve purchased your low friction “tribo-filament”, and you’ve got a printer hot enough to print it…perhaps you want to test the low friction properties yourself?

You can head over to the company GrabCAD library at this link and try printing some bearings yourself. As of writing, there are over 130 different models available, and unlike many companies who offer 3D models of their models (trinkets, basically), many of these ones from Igus are actually useful! And you don’t necessarily need to drop over $100 on their tribo-filaments to print a lot of them. You can use your common-or-garden PLA for a lot of these models.

Take this e-chain for example. Like all of the models on their GrabCAD page, they are available in CAD-agnostic STEP and STL files. This model comprises 24 pieces in total, allowing for full articulation. You could probably even print it in one piece (might be better printing in separate parts though, for optimal orientation). Pretty sure that could be useful on a 3D printer, especially if like me, you have cables trailing all over the place.

E-chain render. (Image credit: Phillip Keane)

If you fancy giving the bearings a try with either the tribo-filament or with your own plastics at home, then you can do that also.

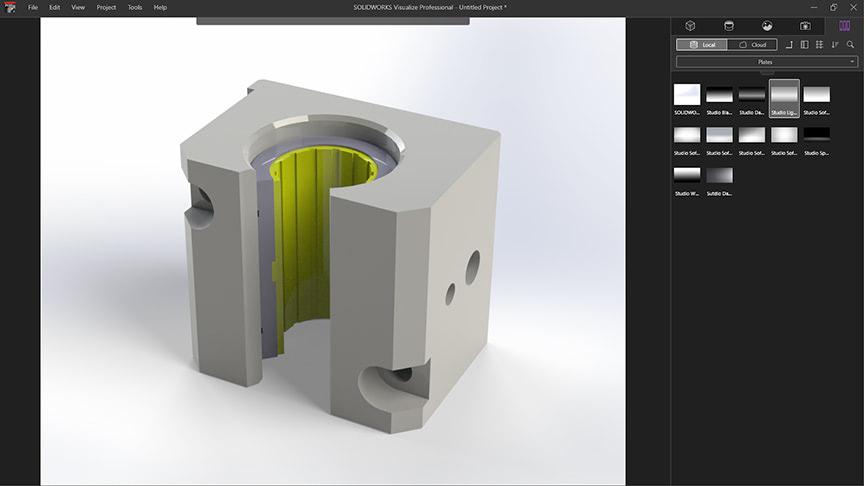

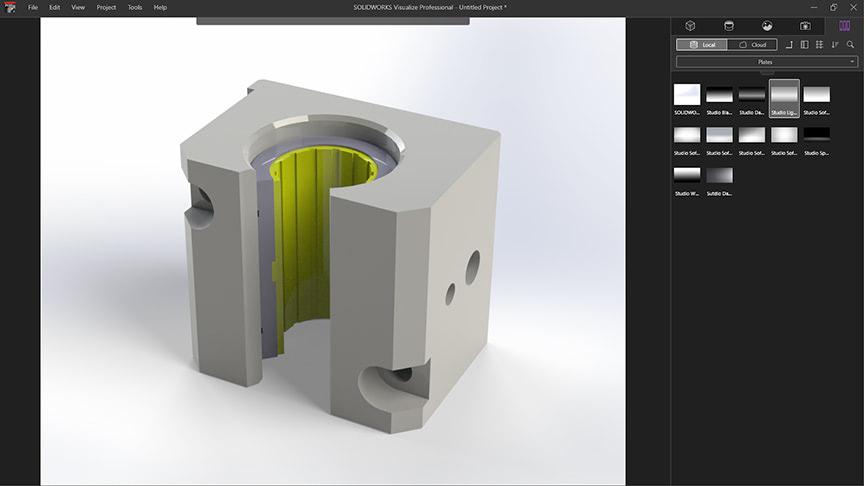

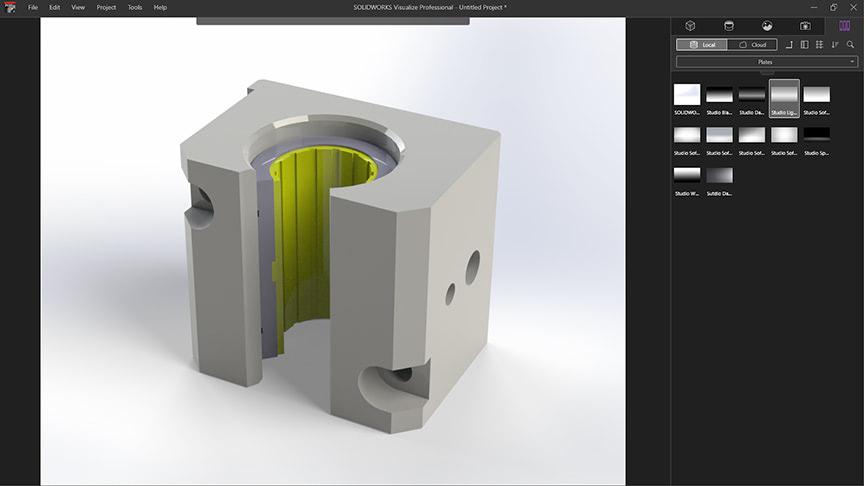

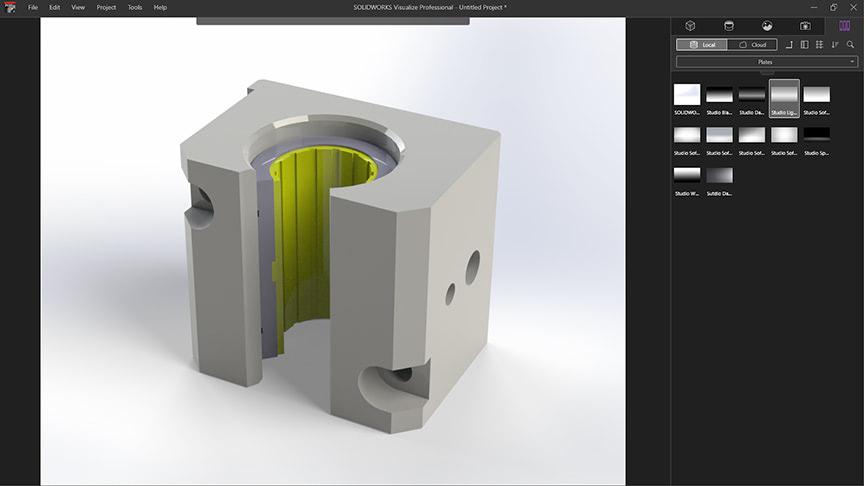

As you can see in the render below, the plastic bearing material is the yellow stuff, and it is held in place by an open-faced pillow block, which would typically be made from steel or aluminium.

Why not print the whole thing in plastic and see how that works out?

It can’t be much worse than those cheap linear bearings, right? And at least you only have to wait a couple of hours to print it rather than wait 3 weeks for it to arrive in the mail.

Open faced pillow block/bearing render. (Image credit: Phillip Keane)

Have you tried printing with these tribo-filaments? How about printing bearings with other plastics? Let us know!