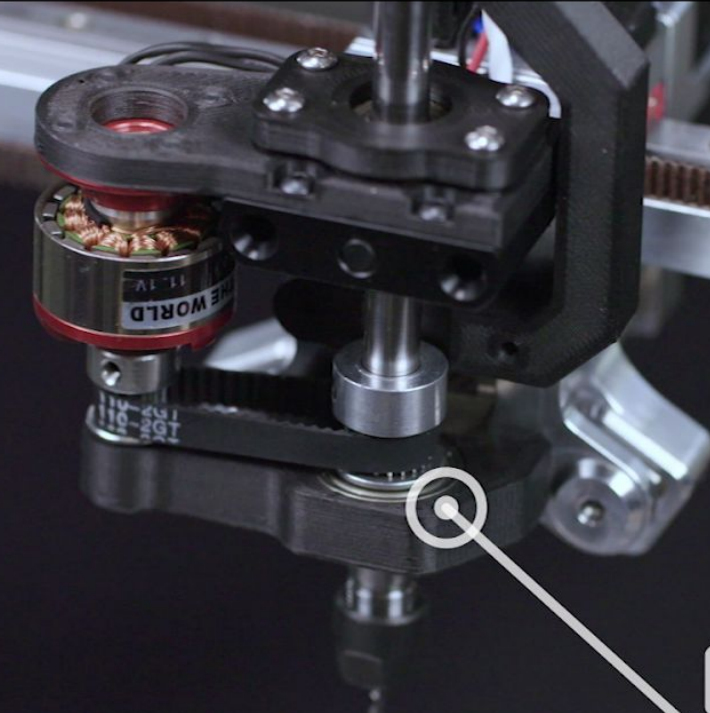

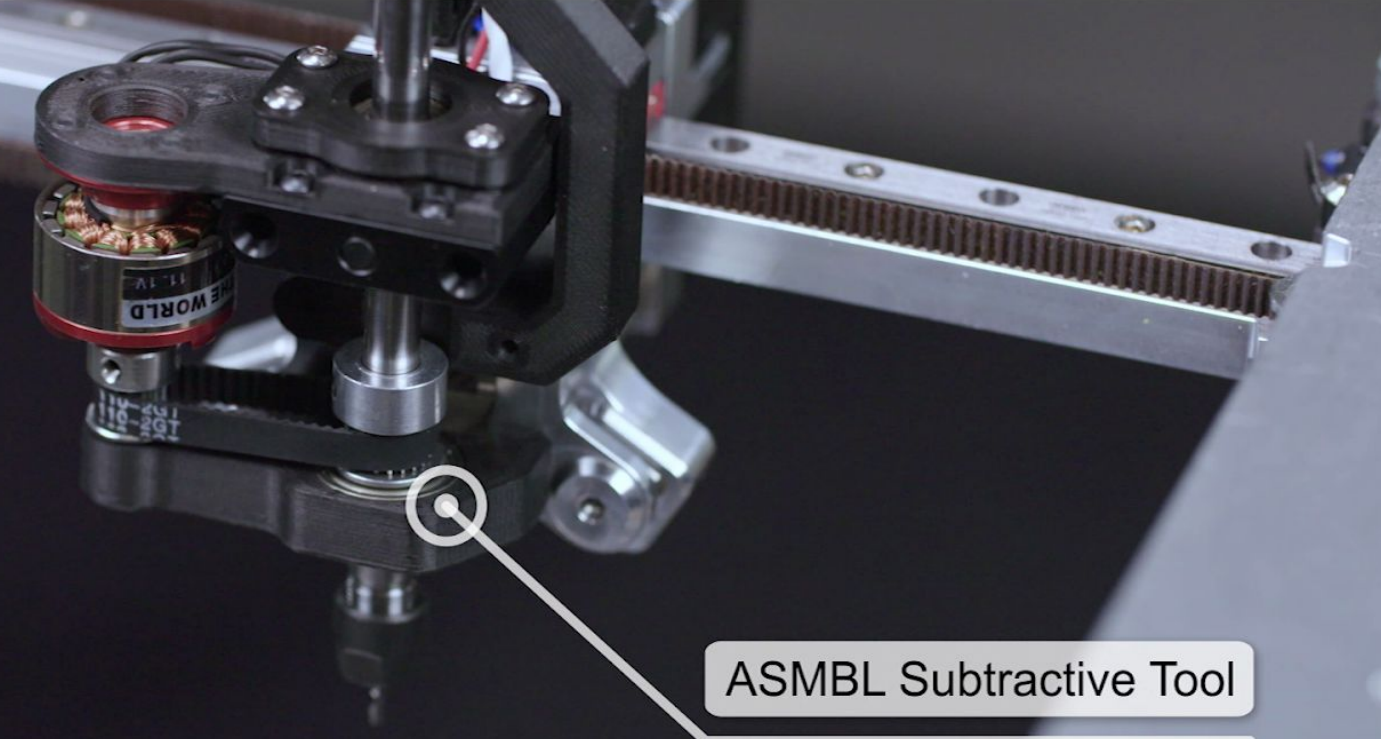

Leading hotend manufacturer E3D has launched a new subtractive toolhead for use with its Motion System and ToolChanger – the ASMBL tool.

The ToolChanger has been available for a year now, and allows users to automatically change toolheads mid-print. With it, the production of multi-material, multi-resolution parts is completely automated. Printheads and extruders are swapped out in a ‘snap on, snap off’ manner, with minimal downtime during substitution.

The ASMBL tool

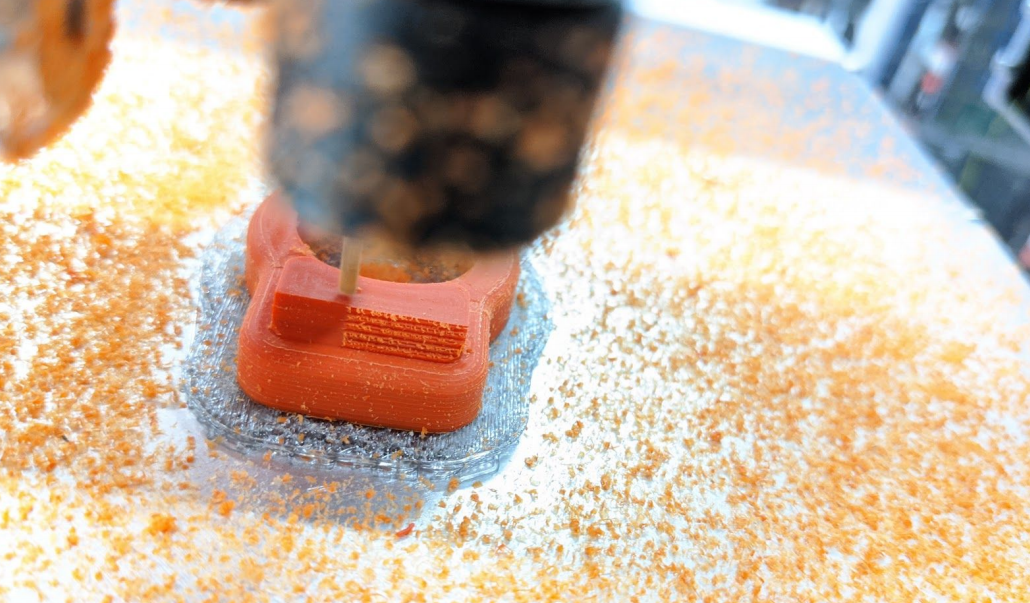

The ASMBL (Additive Subtractive Manufacturing By Layer) tool is a little bit different from the other tools available for the platform, in that it isn’t an additive tool at all. Much like the toolhead found in a traditional CNC milling machine, ASMBL is designed to remove material from a part that’s already been FDM printed. E3D believes that by integrating both additive and subtractive manufacturing into one hybrid machine, it can revolutionize the desktop printing market for good.

One of the key features of the tool is its ability to mill printed faces for a superior surface finish. The characteristic layer line artifacts are completely removed and any roughness is smoothed over by friction. The result is a glass-like surface finish on the side and top faces of the print.

It also has the effect of machining off any out-of-tolerance overhangs and unintentional surface artifacts, fine-tuning the dimensional precision of the part. This is especially useful for holes that are to be used as bearing housings, as precision-machined bearings tend to have extremely tight tolerances.

According to E3D, true square corners are usually extremely difficult to achieve with standard desktop FDM machines due to the shape of the nozzle. ASMBL aims to remedy this, promising sharp corners at 90deg with one pass over the edge of a part. The tool also allows for non-planar milling, whereby all three axes can shift at once. This can be used to mill away the ‘staircase effect’ that can sometimes be observed when particularly thick layers heights are used.

Software integration

ASMBL goes beyond just hardware, as there is even a Fusion 360 plug-in specifically for use with the toolhead. The plug-in allows users to manipulate a 3D file and generate ASMBL g-code directly in Fusion, without the need to generate a second separate STL with the ‘milled off’ changes. According to E3D, this step-saving functionality is only the beginning, and the company is now in talks with Autodesk about a complementary app that makes the ASMBL set-up process easier for the average Fusion user.

The ASMBL tool can turn a regular 3D printer into a hybrid system, albeit a very small one. On a much larger scale, CNC grinding machine manufacturer ANCA recently developed a hybrid 3D printing system for manufacturing custom-designed machining tools. Elsewhere, a joint research project for the development of a highly efficient modular hybrid manufacturing cell was commenced back in April. The eight-partner project is using a multi-axis KUKA robotic arm with an LMD toolhead, making it integratable into existing process chains with ease.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the ASMBL subtractive toolhead. Photo via E3D.