If you like to think of 3D printing as magic—then consider Shapeways file fixers like Angeliki Sioliou to be real-life superheroes.

“We are able to help regenerate many models that originally were not printable,” says Angeliki Sioliou, User Application Design Specialist.

The very epicenter of 3D printing is based on pushing the limits. And while many one-off inventions have served the human race throughout time, the technology of 3D printing is constantly growing and spreading into countless other applications; however, all that fantastic creative energy and intense desire to create new products or improve on old ones are the main reasons file fixers like Angeliki usually have their work cut out for them regarding a variety of uploaded models.

In most cases, designers may be able to upload models successfully and complete an online purchase for 3D printing services. On further inspection though, file fixers like Angeliki may discover details which would affect quality of the print. While many customers may want to work outside the guidelines in terms of technology or materials, often that is where challenges occur.

“Different materials have different guidelines, and sometimes we run into problems when a model is set for a material that isn’t compatible with a more complicated type of geometry,” says Angeliki. “It saves a lot of time to know exactly what material you want to work with and to research its guidelines before designing.“

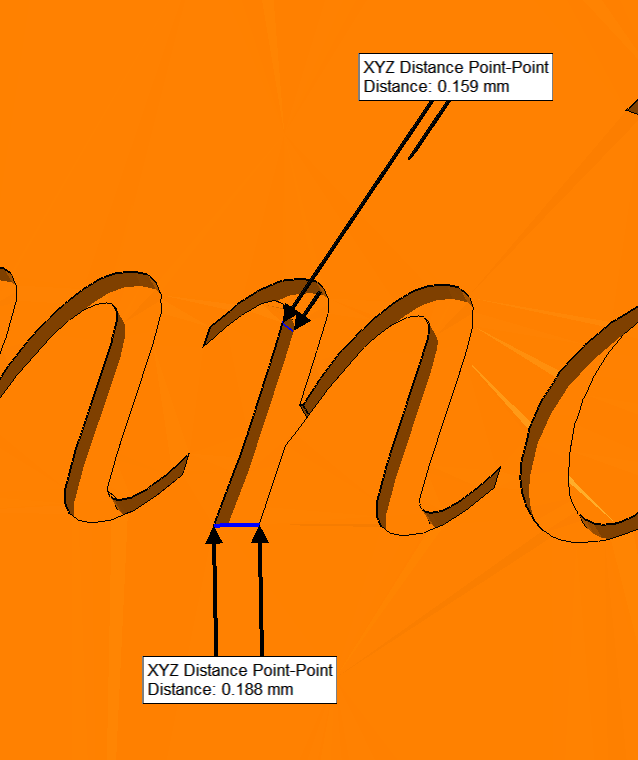

As Angeliki is fond of saying, with 3D printing it’s all about the details, and in working with nearly every material that Shapeways sells, she has continued to see this ring true repeatedly. Designers can avoid much wasted time by making sure that submitted models aren’t reaching outside the limits of a certain material—for example, a customized ring with extremely ornate engraved lettering on the inside could be problematic.

In a case like that, file fixers recommend that designers keep a 1:1 ratio so depth and width of letters are the same. When it comes to 3D printing and any type of engraving, sans serif may also be avoided in different fonts to avoid challenges in clarity.

“Different materials have different common rejections; for example, in steel we often see rejections for weak geometries. In cast metals, we often see rejections for details. Other general rejections are wall thickness—that is one we see typically, all over.”

Texture is another common issue. This is why selection of material is important. For a more basic print—perhaps in an educational application or a quick presentation, customers may not mind going for a more economical material that could show some flaws or slight blemishes in the surface finish.

It all depends on the scope of a project too. For customers still deciding on materials as well as the final design—even for something as small as a personalized ring—they may want to prototype in a more affordable material first. Nylon 12 [Versatile Plastic] is a good choice for making samples or test models, for overall design and fit. The bottom line though is that for customers getting ready to make a print in gold or platinum, it is best to have an organized, knowledgeable approach. That could mean researching guidelines as well as reaching out for help to speak with someone at Shapeways.

In some cases, there may be models that customers realize are not within guidelines, but they are willing to take the risk and have them printed anyway. The “print it anyway” (PITA) option can be a gamble, and expensive—especially when requesting premium materials. Angeliki reports, however, that she has seen some amazing PITA results, resulting in high-quality, highly customized items that everyone is happy with in the end.

And while Shapeways specializes in production of customized products, you may find yourself getting customized feedback too.

“I make sure the model is printable if possible,” says Angeliki, pointing out that from her end, the feedback sent to customers is not coming from a computer system, or a bot, but from her.

“For some models, I add a personalized message at the beginning of a printability rejection.”

Accuracy and repeatability in parts is a result of the enormous effort put into quality assurance and quality control, and one of the greatest advantages for industrial customers working with Shapeways. There can be a small battle in getting there sometimes though when working with a first-time customer or a new part—especially if it just happens to print out perfectly the first time but presents challenges in manufacturing another thousand right away.

“Users pushing the limitations may lead to a lot of file fixing, but we’re guilty of it as a business overall too because we are constantly trying to stretch the guidelines in technology,” said Aidan O’Sullivan, Vice President of Operations at Shapeways.

While a concept may emerge from mere whim, quality prototypes and parts do not. Excellence in design should translate to excellence in products, but that’s a long shot unless there is a good understanding of the manufacturing process and compatible materials.

Making the right choices for your 3D print is critical whether producing a detailed, full-color prototype for an architectural presentation, a high-performance part for a mechanical device, or a piece of fine jewelry meant to endure over time as a precious keepsake.

Joining Shapeways in 2016 as a 3D Printing Engineer in selective laser sintering (SLS), Angeliki quickly became a 3D Model Fixer, and now works as a User Application Design Specialist within the User Application team, collaborating with customers on countless customizations, as well as focusing on fixing files that are not printable, maintaining the quality of rejected models, and supporting customer service and supply chain teams in resolving model issues.