We recently explored how Formula 1 has embraced 3D printing to fabricate car parts, test prototypes, and even guide regulatory decisions. Suffice to say, F1 and AM are now tightly intertwined. Youtuber Indeterminate Design (ID) is taking that relationship to another level with his fully functional 3D printed F1 gearbox.

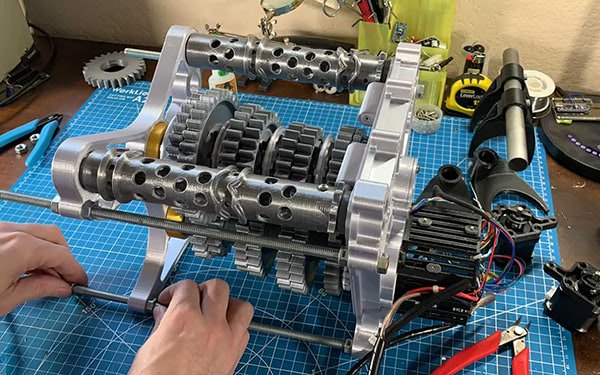

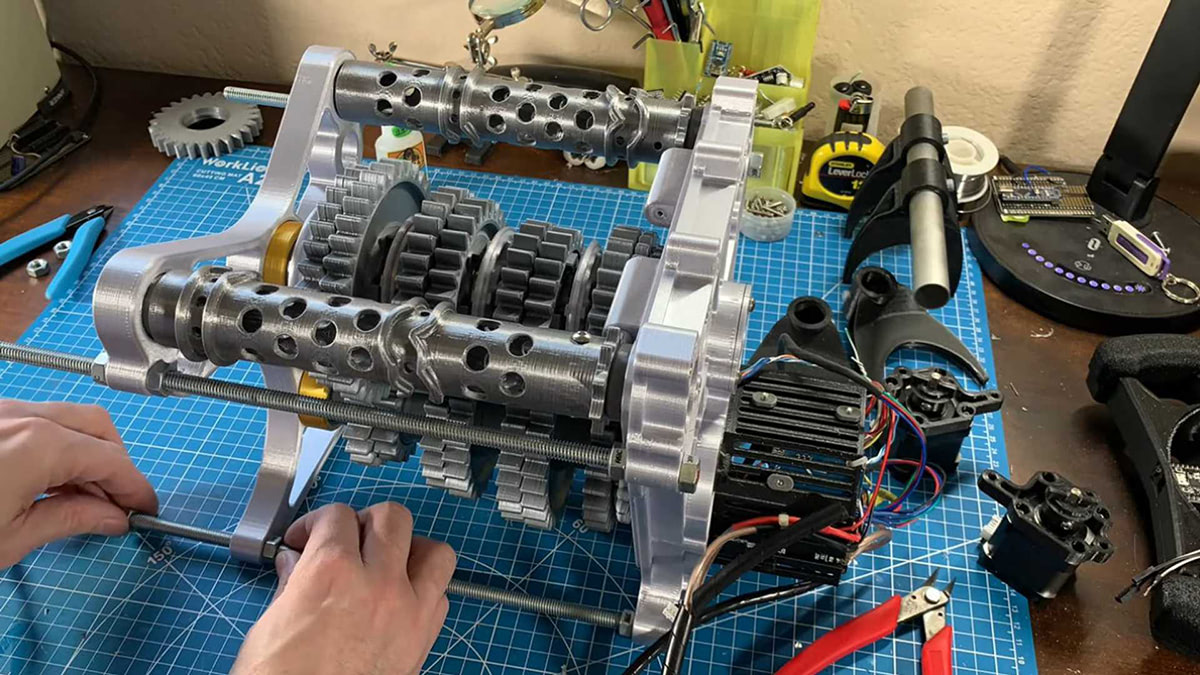

Over a series of videos, ID details the lengthy process of designing, printing (300+ hours), and assembling the 1:1 scale model. In the first video, he describes the technical difficulties an F1 gearbox has to overcome, like managing the torque of 1,000 horsepower and 15,000 RPMs, all within the space of 180mm. He also demonstrates the assembly of the main gear clusters and the gear selector barrels. By the second video, he dives into the motors and electronics; an RC motor is used for the main drive shaft and Nema 17 stepper motors (commonly found on 3D printers) actuate the gear shifts. The third video focuses on his efforts in getting the shifting to work electronically and testing the max RPMs. Part four is dedicated to the software and control systems he created to run the gearbox as well the housing that fits all of the electronics. And the printed F1 style steering wheel with paddle shifters really ties the project together. By the fifth video, he puts it all together and shows the paddle shifters wirelessly shifting the gears with the motor running. It’s pretty amazing.

3D Printed Working Model of an F1 Gearbox. Image credit: Indeterminate Design

Sequential gearboxes are engineering marvels, especially the kind used in F1 where everything has to be packed into such a tiny space. The tolerances are incredibly tight and there’s little room for error. ID printed all of the parts on a simple DIY 3D printer and most of the parts were printed in PLA so the success of the project is a testament to the engineering skills of ID.

In the series he shares a couple tricks to help with tolerances of printed parts, such as applying super glue to rough areas and then sanding them smooth, or wrapping a layer of packing tape around shafts to reduce friction on the gears.

ID has done a fantastic job of demonstrating that inexpensive 3D printers and materials can be employed to create incredibly complex assemblies.