A novel, fast-setting ceramic-based bioink could allow surgeons in the future to 3D print bone with living cells to repair damaged bone tissue. Scientists from the University of New South Wales (UNSW) in Sydney, Australia, used a LulzBot Mini desktop 3D printer and customized bioink to fabricate complex bone-like structures at room temperature without the need for harsh processing conditions that require invasive chemicals, radiation, or postprocessing steps. The new biofabrication strategy can create bone mimicking constructs for bone tissue regeneration. Eventually, the process could generate custom bone microenvironments for disease modeling, multicellular delivery, in vivo bone repair, and even allow integration with sensitive biomolecules and drugs for controlled release.

Inspired by the bone process where living organisms produce minerals, the scientists developed a new technique, dubbed ceramic omnidirectional bioprinting in cell-suspensions (COBICS), enabling them to print bone-mimicking constructs that harden in minutes when placed in water. In a paper published in the journal Advanced Functional Materials, the authors describe how they developed a special calcium phosphate bioink in a microgel matrix with living cells. The study demonstrated that mineralized constructs could be deposited within a high density of stem cells, directing the cellular organization, and inducing osteogenesis in vitro.

While the idea of 3D printing bone-mimicking structures is not new, this is the first time such material can be created at room temperature – complete with living cells – and without harsh chemicals or radiation. Senior study author Iman Roohani, a researcher at UNSW’s School of Chemistry and leader of the Biomaterials Design and Tissue Engineering Lab at UNSW, explained that this is a unique technology to produce structures that closely mimic bone tissue.

“It could be used in clinical applications where there is a large demand for in situ repair of bone defects such as those caused by trauma, cancer, or where a big chunk of tissue is resected,” he specified.

Examples of computer-generated 3D models (top) and corresponding 3D printed bone-like structures (bottom) through COBICS technique. Image courtesy of University of New South Wales (UNSW).

The breakthrough technology was co-developed by Roohani and Associate Professor at UNSW’s School of Chemistry, Kristopher Kilian. He described the process as a significant advance on current state-of-the-art technology. Until now, making a piece of bone-like material to repair a patient’s bone tissue involves first going into a laboratory to fabricate the structures using high-temperature furnaces and toxic chemicals, emphasized the study co-author. The resulting dry material is then brought into a clinical setting or a laboratory, where it is profusely washed before living cells are added to it.

Bone defects resulting from injury or disease usually need surgical procedures. Conventional treatment options include shortening the bone, using a metal external frame to help create new bone and bone grafts. Bone defect repair is one of the most common regenerative procedures, with more than two million bone grafts performed worldwide annually. However, these proven procedures are associated with variable clinical outcomes of postsurgical morbidity, especially at the donor site, and increased surgical costs. The field of regenerative medicine could hold immense potential to overcome these limitations by repairing bone with live 3D printed tissue. Although still a nascent sector, relevant advances in the past years have improved cell understanding, bioink development, and bioprinting processes to guide the technology into the future.

Powered by Aniwaa

According to Kilian, no technologies can directly extrude the bioink into an area with cells, like a cavity in a patient’s bone. He suggested that surgeons could “go directly into the bone with this technique,” where there are cells, blood vessels, and fat, and “print a bone-like structure that already contains living cells.”

The study originated after co-authors Thomas Molley, and Stephanie Nemec attended a Regenerative Biomaterials & Therapeutics Group workshop at Carnegie Mellon University (CMU) led by Professor of Biomedical Engineering and inventor of the FRESH technique, Adam Feinberg. The researchers ended up taking home printers from CMU in Pennsylvania. Kilian pondered on a Twitter post: “We were stabilizing microgels for cell culture, which begged the question: Can microgel baths support ceramic filaments?.”

The team got to work, demonstrating they could print complex bone-mimetic architectures. This allowed the printed ceramic to be harvested like FRESH or integrated with a suspension of chemically crosslinked microgels and live cells, Kilian went on. The authors claim that when the ink is combined with a collagenous substance containing living cells, it enables in-situ fabrication of bone-like tissues. This process may be suitable for bone tissue engineering applications, disease modeling, drug screening, and in-situ reconstruction or replacement of bone and osteochondral defects directly in the clinic, using patients’ cells in real-time.

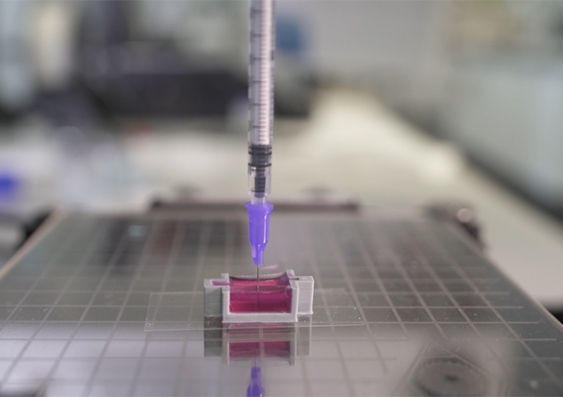

Researcher and study Co-author Sara Romanazzo prepares to use a LulzBot Mini to 3D print a piece of bone using the COBICS technique. Image courtesy of University of New South Wales (UNSW).

“The ink takes advantage of a setting mechanism through the local nano crystallization of its components in aqueous environments, converting the inorganic ink to mechanically interlocked bone apatite nanocrystals,” said Roohani. “In other words, it forms a structure that is chemically similar to bone-building blocks. The ink is formulated in such a way that the conversion is quick, non-toxic in a biological environment, and it only initiates when ink is exposed to the body fluids, providing an ample working time for the end-user, for example, surgeons.”

The new bone 3D printing process could open up a whole new way of treating and repairing bone tissue, so the study has already caught the attention of interested surgeons and medical technology manufacturers. Kilian hopes that one day, a patient needing a bone graft can walk into a clinic where their bone’s anatomical structure is imaged, translated to a 3D printer, and directly printed into the cavity with his or her cells. Next up, the duo will be performing in vivo tests in animal models to see if the living cells in the bone-like constructs continue to grow after being implanted in existing bone tissue and invite dentists, orthopedic surgeons, bone scientists, and research institutes to explore the potential of their COBICS technique to create synthetic bone matrices in situ.